Power cables are an essential component in every electrical system, whether it’s powering a household industrial plant, or a complex infrastructure project. However, in order to perform optimally, cables must endure and adapt to various environmental challenges.

Harsh environmental conditions ranging from extreme temperatures to moisture, UV radiation, mechanical stress, and chemical exposure pose significant threats to the long-term durability of power cables.

The failure to account for these conditions during cable selection or installation can lead to expensive repairs, downtime, and even safety hazards.

Choosing the right power cable involves understanding how different environmental factors affect cable performance and lifespan.

Manufacturers have developed advanced cable designs, insulation materials, and protective coatings to tackle these head-on challenges.

This guide will help you navigate these considerations, offering insights into the key features and standards that ensure cable durability under tough environmental conditions.

We will explore the impact of different harsh environments on power cables and the technologies that make modern cables more resilient than ever.

In this guide, we will explain how to make informed choices for power cables that will last and perform well even under the most demanding conditions.

Power cables are subjected to various environmental factors that can impact their performance and lifespan.

Understanding these challenges is crucial for selecting cables that can handle the specific conditions in which they will be used.

Below are some of the main environmental challenges that affect the durability of power cables:

Temperature Extremes

One of the most critical factors influencing cable durability is temperature. Extreme temperatures, both high and low, can degrade the cable’s insulation and materials, leading to failure.

High temperatures cause materials to soften or melt, compromising insulation and overall cable integrity. Low temperatures, on the other hand, can cause materials to become brittle, increasing the risk of cracking or breaking.

It has specific temperature ratings, typically ranging from -40°C to 90°C. When exposed to temperatures beyond these limits, the cable’s performance can decline.

This is particularly problematic for outdoor cables or cables used in extreme climates. In such cases, special insulation materials are required to withstand temperature extremes and ensure safe operation.

UV Radiation

Outdoor power cables, particularly those exposed to direct sunlight, face the challenge of UV radiation.

UV rays from the sun can break down the chemical structure of the cable’s insulation, causing it to become brittle, cracked, or discolored over time. This can lead to failure of the cable, especially when exposed to prolonged sunlight.

To mitigate this, cables are often made with UV-resistant materials or treated with coatings that protect against UV degradation.

However, continual exposure to UV rays can still reduce the lifespan of the cable, so selecting UV-resistant cables for outdoor use is crucial for maintaining long-term reliability.

Moisture and Water

Moisture and water are two of the most damaging environmental factors for power cables. Water can seep into the cable through cracks or gaps in the insulation, causing short circuits, corrosion, and potential failures.

It is exposed to direct water sources, like rain or flooding, or those buried underground, are at particular risk.

Water-resistant and waterproof cables are commonly used in such situations. These cables feature materials that prevent water from penetrating the core, such as waterproof coatings or water-blocking agents.

For underground or submerged applications, cables are designed with additional sheathing and sealing to ensure moisture resistance.

Chemical Exposure

Power cables in industrial settings are often exposed to various chemicals, including oils, solvents, acids, and other corrosive substances.

These chemicals can weaken the outer sheath and insulation materials, causing the cable to degrade faster and eventually fail.

In such environments, cables made with chemically resistant materials such as XLPE (cross-linked polyethylene) or EPR (ethylene propylene rubber) are necessary.

These materials are engineered to withstand exposure to harmful chemicals without compromising the cable’s performance or safety.

Mechanical Stress

Mechanical stress is another significant factor that can compromise the durability of power cables. Whether due to heavy traffic, vibrations, or physical impacts, cables can suffer from abrasion, crushing, or stretching.

In high-stress environments such as mining, construction, or manufacturing plants, cables are frequently exposed to these physical forces, which can cause them to wear out or fail prematurely.

To combat this, cables used in high-stress applications are often armored with steel or other durable materials to prevent physical damage.

Additionally, flexible cables are designed to handle bending, stretching, and movement without losing their structural integrity.

To ensure that power cables perform reliably under harsh environmental conditions, they must be designed with specific features that enhance their durability.

These features play a crucial role in improving cable resistance to temperature fluctuations, moisture, chemicals, and physical stress.

Below are some of the key features that contribute to the improved durability of these cables.

Insulation Materials

The insulation material used in a power cable is its first line of defense against environmental factors. Insulation serves to protect the conductor from short circuits, prevent electrical leaks, and shield the cable from external stresses.

Different types of insulation materials are designed to withstand specific environmental challenges:

1. Polyvinyl Chloride (PVC): Common in low-voltage cables, PVC offers good resistance to weather conditions, heat, and oils.

2. Cross-linked Polyethylene (XLPE): Known for its thermal stability, XLPE is often used in medium to high-voltage cables. It can withstand both high temperatures and chemical exposure.

3. Rubber Insulation: Used in cables that require high flexibility, rubber is resistant to high temperatures, mechanical stresses, and chemical exposure, making it ideal for industrial applications.

Choosing the right insulation material depends on the environmental conditions and the application in which the cable will be used. A proper insulation material ensures better durability and performance in extreme conditions.

Protective Jacket

The outer jacket of a power cable serves as a protective barrier against environmental factors like UV radiation, moisture, and physical impacts.

These cables used in harsh environments typically feature reinforced jacketing to enhance their durability. Key materials used in protective jacketing include:

1. Polyurethane (PU): Known for its resistance to abrasion, PU coatings are commonly used in high-mechanical stress environments.

2. Low Smoke Zero Halogen (LSZH): These jackets are flame-retardant and produce less smoke in the event of a fire, making them ideal for environments where fire safety is a concern.

3. Thermoplastic Elastomers (TPE): A flexible and durable material used for cables that need to bend and move while resisting external damage.

The choice of jacketing material plays an essential role in protecting cables from external stresses like UV rays, physical damage, and chemical exposure, thus extending their service life.

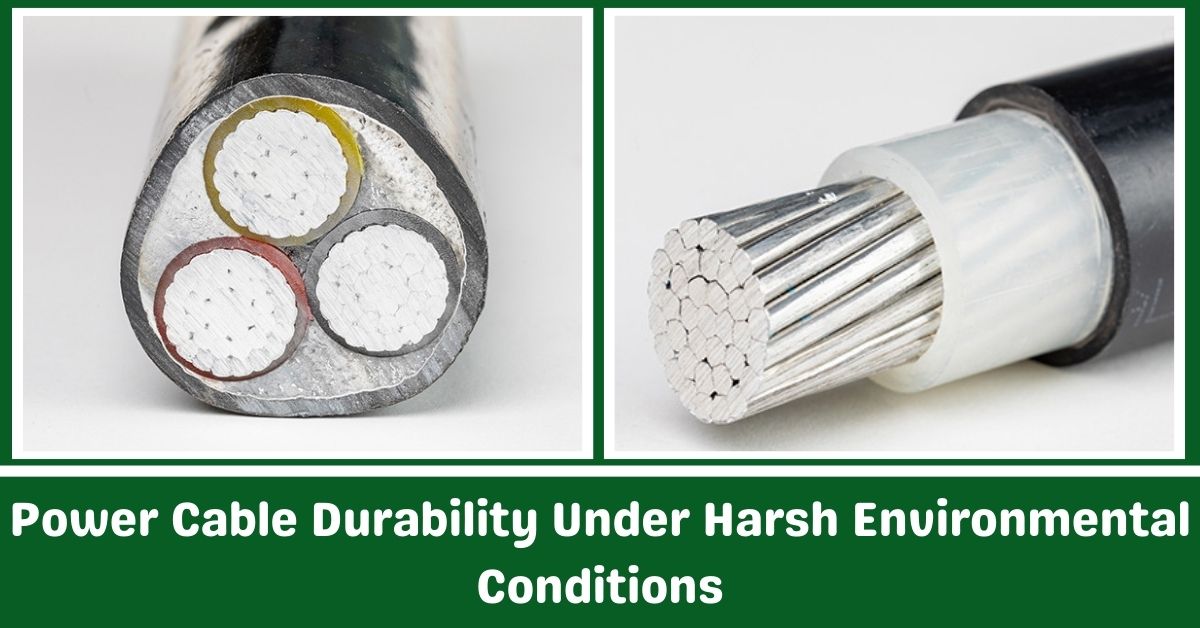

Armoring and Shielding

In environments where cables are subject to significant mechanical stress, armoring is used to provide additional protection.

Armored cables feature a metal layer, typically made from steel or aluminum, which helps protect the cable from physical impacts, crushing, or abrasion.

This is particularly important for cables installed in areas with heavy traffic, such as factories, construction sites, or mining areas.

Additionally, cables are often shielded to protect them from electromagnetic interference (EMI) and to ensure that the electrical signals within the cable remain clean.

Shielding can be made of materials like copper or aluminum and is particularly useful in sensitive applications like data transmission or high-voltage power systems.

Fire Resistance

In certain environments, fire safety is of utmost importance. Power cables are available with fire-resistant properties, which help prevent the spread of fire in the event of an electrical fault or fire hazard.

These cables are made with materials that can withstand high temperatures without igniting, such as fire-resistant insulation or jacketing.

For critical applications, such as in public buildings, underground facilities, or industrial settings, using fire-resistant cables can significantly reduce the risk of fire-related hazards.

The durability and reliability of power cables are not left to chance. There are strict industry standards and testing procedures that ensure cables meet the necessary requirements for performance and safety.

These standards take into account the challenges posed by different environmental conditions and ensure that cables are manufactured to withstand them.

International Electrotechnical Commission (IEC) Standards

The IEC provides global standards for electrical and electronic equipment, including power cables.

One of the most widely referenced standards is IEC 60502-1 , which outlines the specifications for medium-voltage cables used in power distribution.

This standard specifies the construction, materials, and testing requirements for cables to ensure they perform reliably under various environmental conditions.

Underwriters Laboratories (UL) Standards

UL 44 is another widely recognized standard, particularly in the United States. It sets requirements for cables used in industrial and commercial applications.

UL tests cables for their ability to withstand exposure to various environmental factors, including high temperatures, moisture, and mechanical stresses.

British Standard BS 7870

In the UK, the BS 7870 standard specifies the requirements for cables used in outdoor, underground, and industrial environments.

The standard ensures that cables meet stringent requirements for water resistance, fire safety, and mechanical protection.

Testing Procedures

Manufacturers subject power cables to a range of tests to ensure they meet the relevant standards. These tests include:

1. Temperature cycling tests to evaluate the cable’s ability to withstand extreme temperatures.

2. Moisture penetration tests to check how well the cable resists water damage.

3. Chemical exposure tests to assess the cable’s resistance to oils, solvents, and other chemicals.

4. Mechanical stress tests to simulate conditions like crushing, abrasion, and vibration.

Testing ensures that cables are durable enough to handle the demands of real-world environments.

Durability is critical for power cables used in various applications, from outdoor installations to industrial plants. Cables must be able to endure harsh environmental factors and continue to perform reliably over time.

In real-world applications, durability is especially important in industries like mining, construction, and marine, where these cables are exposed to extreme conditions.

This used in these industries must meet specific durability standards, with armoring, fire-resistant materials, and waterproof coatings to ensure that they can handle the demanding environments in which they are installed.

In marine environments, for example, cables are often exposed to saltwater, moisture, and extreme temperatures, requiring robust construction and corrosion resistance.

Similarly, cables used in industrial applications need to be resistant to chemical exposure and physical stress.

Power cable durability under harsh environmental conditions is not a matter of chance it relies on selecting the right materials, construction techniques, and adherence to rigorous industry standards.

From extreme temperatures and UV exposure to moisture, chemicals, and mechanical stress, each environmental factor poses a specific threat to cable performance.

However, these challenges can be effectively managed through thoughtful cable design, including robust insulation, protective jacketing, armoring, and proper shielding.

Understanding how cables are tested and rated gives end-users the confidence to choose the right product for each application, whether for industrial sites, outdoor grids, underground networks, or marine installations.

Investing in high-quality, durable cables ultimately reduces downtime, extends service life, and lowers maintenance costs.

Durability is not just a technical specification it’s a practical necessity for safe and efficient operations in demanding conditions.

In environments where reliability is critical, durable power cables are not optional they are essential.

By choosing cables engineered for the environment they’ll face, users can ensure long-term electrical performance and system safety.