Concentric cables play a critical role in modern electrical distribution systems, particularly in underground and utility-scale installations.

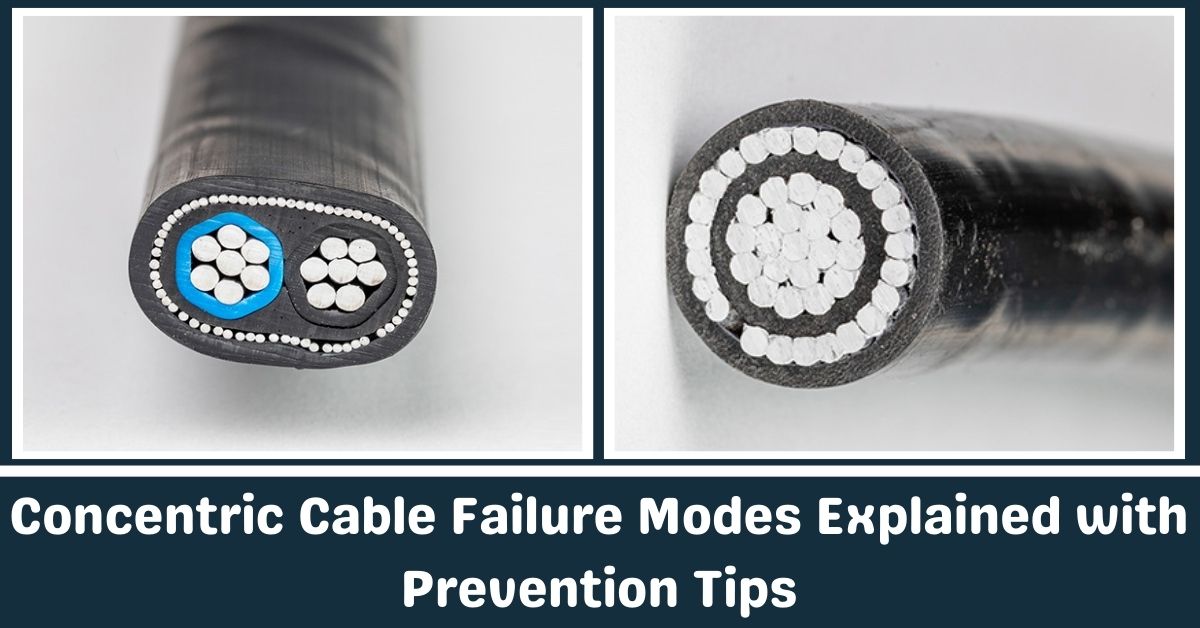

Designed with a central conductor surrounded by concentric neutral wires and protective insulation, these cables provide a reliable return path for fault currents and help ensure stable voltage delivery.

Despite their durability, concentric cables are not immune to failure.

Over time, and especially under poor installation or harsh environmental conditions, various failure modes can emerge from mechanical damage and moisture ingress to insulation breakdown and neutral wire corrosion.

Each of these issues can lead to costly outages, safety hazards, and time-consuming repairs. Understanding why and how these failures occur is essential for engineers, contractors, and maintenance teams.

Preventing them doesn’t always require expensive tools often, it’s about proper handling, using the right materials, and following proven best practices from the start.

In this guide, we will explain the most common concentric cable failure modes and provide clear, practical tips to help you prevent them effectively.

Concentric cables are essential for power distribution systems, particularly in underground or direct-buried applications. They serve both as a conductor and as a neutral return path, often doubling as a grounding system.

A failure in these cables can lead to a wide range of consequences from system outages and voltage imbalance to severe safety hazards such as electrical shock and fires.

Failures in these cables are not just technical issues; they also result in real-world operational downtime and expensive repairs.

For utility companies and contractors, this means service disruptions and customer dissatisfaction. For industrial or commercial setups, it may lead to equipment damage or halts in production.

Additionally, a single point of failure in a this cable often affects a larger network of components.

Because the neutral wires are wrapped around the main conductor, any degradation in their conductivity impacts the cable’s ability to properly return current or maintain safe grounding.

This introduces risk not just to the electrical system but also to personnel safety.

Understanding the failure modes of these cables allows teams to reduce these risks, plan better installations, and avoid costly problems in the long run.

Concentric cables fail for several reasons. Each failure mode is rooted in physical, chemical, or mechanical deterioration. Below are the most common types.

Moisture Ingress

Water penetration is one of the leading causes of concentric cable failure. If water enters the cable sheath often due to cuts, poor sealing, or joint faults it can corrode the concentric neutral wires.

Corrosion reduces conductivity, increases resistance, and over time causes overheating or arcing.

Neutral Wire Corrosion

The concentric neutral wires are typically made of copper or aluminum. In underground installations, if the cable is not properly sealed, or if it’s exposed to chemicals in the soil, these wires corrode over time.

This weakens the ground fault current path and may cause protection devices to fail during faults.

Insulation Breakdown

Aging, thermal overload, or physical damage can lead to insulation breakdown. Once insulation fails, it can cause direct short circuits or partial discharge activity.

Over time, this creates hotspots and localized cable failures.

Mechanical Damage

This includes nicks, cuts, or crushing of the cable during transportation, handling, or installation.

If the concentric wires are physically damaged, their structural and electrical integrity is compromised, even if not immediately noticeable.

Overheating

Overloaded cables generate excessive heat. If not managed properly, especially in poorly ventilated or direct-buried environments, this can accelerate the breakdown of insulation and lead to thermal damage in the neutral wires.

Poor Terminations

Improper terminations are another major cause of failure. Loose connections, inadequate crimps, or improper sealing can allow moisture ingress, introduce high resistance, or result in arcing under load.

Electrochemical Treeing

This is a gradual failure of insulation caused by electrical stress in the presence of moisture and contamination. It’s more likely in older cables and can take years to develop, making it difficult to detect until it’s too late.

Understanding these failure modes helps prioritize what to inspect during maintenance or pre-installation quality checks.

Detecting early signs of failure in concentric cables is crucial for avoiding system downtime and preventing hazardous events.

While complete diagnostics may require professional tools, many indicators can be monitored during routine inspections.

Visual Inspections

Regular inspection of visible cable sections can reveal early signs such as cracks, swelling, discoloration, or damaged outer jackets. In exposed areas, signs of corrosion on neutral wires or connectors are warning signals.

Infrared Thermography

Infrared scans detect hotspots along cable runs and terminations. Any temperature anomaly usually indicates excessive resistance, possibly from corrosion or loose connections.

Periodic thermal imaging is highly effective in identifying issues before they lead to complete failure.

Insulation Resistance Testing

A Megger test can assess insulation health. Decreasing resistance over time indicates progressive insulation breakdown. This test should be part of a routine preventive maintenance program, especially in high-load areas.

Time Domain Reflectometry (TDR)

TDR is used to locate faults or anomalies along the length of a cable. It sends a signal through the cable and measures the reflection caused by impedance mismatches. This can detect water ingress points, open circuits, or damaged insulation.

Neutral Integrity Checks

Simple continuity tests can help check for breaks or excessive resistance in the concentric neutral. For critical systems, more advanced monitoring equipment may be used to measure unbalance in neutral current flows.

Early identification of cable failure potential allows teams to schedule repairs proactively, reducing both risk and downtime.

Proper installation of concentric cables is the first and most effective step in preventing future failures. Below are key practices that ensure a reliable and safe cable setup.

Use Proper Bending Radius

Cables should be installed with a bending radius as specified by the manufacturer. Tight bends can stress insulation and crack the concentric wire arrangement, creating a point of weakness for mechanical and electrical failure.

Avoid Excessive Pulling Tension

During cable pulling, apply tension within the recommended limits. Over-tensioning can stretch or break the concentric wires. Always use pulling grips or baskets designed for the specific cable size.

Correct Cable Sealing

Ensure that all terminations and joints are properly sealed using heat-shrink or cold-shrink products rated for underground or outdoor exposure. Water ingress at joints is a primary cause of long-term failure.

Use Concentric Connectors Designed for the Cable Type

Select compression connectors that are designed for concentric neutral wires. Improper connectors result in uneven contact and may increase resistance, leading to heating and failure.

Protect from Sharp Edges and Compression

Route cables away from sharp surfaces or edges. If installed through conduit or duct, ensure edges are smooth and cables are not pinched or crushed during installation.

Correct Cable Splicing and Jointing

Use factory-approved joint kits. Follow step-by-step instructions carefully, particularly in aligning the concentric wires and sealing layers. Avoid shortcuts improper splices are one of the most common failure points.

Grounding and Bonding

Make sure the concentric neutral is properly bonded at all required points. Grounding should meet local codes and standards. A poorly bonded system reduces safety and can result in circulating currents or voltage rise on metallic parts.

Installing concentric cables with precision and care is essential for their long-term function and safety.

Maintenance ensures concentric cables remain functional and safe throughout their service life.

While these cables are often buried or installed in inaccessible locations, scheduled monitoring and testing extend reliability and prevent emergency failures.

Regular Inspections of Accessible Points

Inspect exposed cable ends, terminations, and junctions. Check for signs of wear, corrosion, or insulation damage. Clean and retorque connection points as per recommended intervals.

Monitor Load Currents and Imbalances

Use load monitoring to ensure the cable is not overloaded. Unbalanced currents across phases or the neutral can indicate issues in the concentric wire circuit or grounding system.

Check for Neutral Corrosion Periodically

In underground systems, periodic soil testing and inspection of neutral resistance can help detect corrosion early. If resistance increases or current flow through the neutral drops unexpectedly, investigate further.

Environmental Protection

If cables are exposed to moisture or chemicals, verify that their jackets are intact and that environmental protection barriers (such as conduits or waterproof coatings) are in good condition.

Thermal Imaging and Electrical Testing

Annual or bi-annual thermographic inspections and insulation testing provide data trends. Even small shifts in resistance, temperature, or insulation values can help anticipate problems.

Document and Track Testing Results

Keep a detailed record of all tests and inspections. Trending this data helps identify degradation patterns and supports predictive maintenance planning.

Consistent maintenance is key to maximizing service life and avoiding avoidable breakdowns.

Use this checklist as a quick reference for minimizing concentric cable failures:

1. Use manufacturer-recommended bend radius and pulling tension

2. Inspect cables visually before and after installation

3. Seal all terminations and joints properly against moisture

4. Use compatible connectors and compression tools

5. Avoid mechanical stress during and after installation

6. Perform insulation resistance testing periodically

7. Conduct thermal imaging of terminations and junction boxes

8. Monitor neutral current and ground resistance

9. Track and trend test results for early problem detection

10. Schedule regular maintenance, especially in high-load systems

Concentric cables are a vital component in electrical distribution, especially for underground and utility systems where reliability and safety are non-negotiable.

Despite their robust design, these cables are prone to specific failure modes including moisture ingress, corrosion, insulation breakdown, mechanical damage, and overheating all of which can lead to serious operational and safety risks if left unaddressed.

The good news is that most of these failures are preventable with proper installation, regular inspection, and adherence to proven maintenance practices.

By focusing on correct sealing, avoiding physical stress, using compatible connectors, and performing routine testing such as thermal imaging and insulation resistance checks, teams can significantly reduce the chances of failure.

Preventive maintenance isn’t just about avoiding downtime it’s about ensuring long-term cable performance, reducing repair costs, and keeping personnel and systems safe.

Staying proactive, rather than reactive, makes a real difference in the field. With the right practices and awareness of early warning signs, concentric cable reliability can be maintained for decades.