Concentric cable is a specialized type of electrical cable designed for reliable and efficient power distribution in both residential and commercial systems.

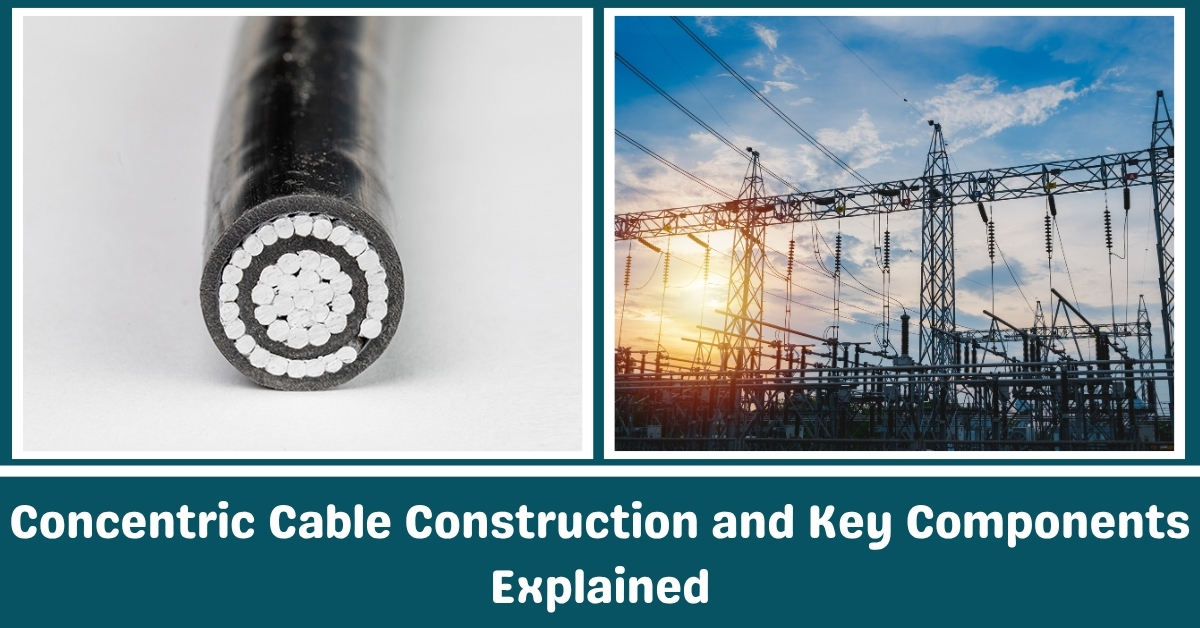

Its unique construction features a central conductor surrounded by a helically wound layer of neutral or grounding wires, all enclosed within protective insulation and an outer jacket.

This design provides balanced electrical performance, superior fault protection, and consistent grounding, making it a preferred choice for utility companies and electricians working on service drops, underground networks, and meter connections.

Unlike standard cables, concentric cables are engineered to handle environmental stress, electrical faults, and mechanical wear with greater resilience.

They are commonly used in applications where system safety, durability, and compliance with electrical codes are essential.

Whether you’re an installer, engineer, or procurement specialist, understanding how these cables are built and what each component does is crucial for making informed decisions and ensuring long-term performance.

Concentric Cable Construction and Key Components Explained

In this guide, we will explain the complete construction of Concentric Cable along with its key components, functions, applications, and technical advantages.

1. Problem: Unreliable Power Transmission Risks Lives and Systems

In any electrical system, the consistent and safe delivery of power is essential. When cables fail, the results can include power outages, equipment malfunctions, and in more serious cases, fire or electrical hazards.

A key contributor to such failures is the use of poorly constructed or inappropriate cables. If the grounding system is weak or the insulation breaks down under stress, it can compromise the entire power network.

In many settings especially utilities and residential service drops—there is a demand for cables that not only transmit electricity efficiently but also ensure safety, durability, and easy fault management.

Traditional cable designs may not always provide adequate grounding or mechanical protection, particularly in underground or exposed installations.

These shortcomings increase operational risk and maintenance costs. A cable must be robust, stable under load, and constructed to meet strict electrical safety codes.

Without reliable cable construction, system performance drops, and risks increase.

2. Agitation: When Cable Failure Becomes a Chain Reaction

When an electrical cable fails, it rarely happens in isolation. Failure in a grounding path, insulation breakdown, or corrosion in the neutral conductor can quickly escalate into a system-wide issue.

A damaged cable might result in improper voltage levels, power loss to homes or equipment, or increased resistance that overheats the cable.

In larger installations, such issues can trigger circuit protection systems, causing widespread blackouts or equipment shutdowns.

Even in small-scale settings like residential services, a faulty cable can lead to malfunctioning appliances, increased electricity bills, or compromised safety.

Over time, repeated faults can degrade infrastructure, increase inspection frequency, and push operational costs up.

All of this highlights the need for cable solutions that are designed with multiple layers of protection, durability, and compliance in mind.

Preventing such chain reactions starts with understanding cable construction and using the right cable in the right application.

3. Solution: Understanding Concentric Cable Design

Concentric cable offers a structured solution to these reliability problems. Its construction is based on a central conductor that is insulated and then surrounded by a helically wound layer of neutral or grounding conductors.

This design allows for balanced current flow and an immediate path to ground during faults. Because of its symmetric configuration, concentric cable maintains uniform electrical and mechanical performance.

The outer conductors, often made of copper or aluminum, are connected to ground, and they play a critical role in returning current and stabilizing voltage levels.

This type of cable also makes visual inspection easier because the grounding layer is exposed and can be quickly checked. The insulation and jacket layers protect the conductors from moisture, chemicals, and mechanical damage.

By combining these elements, concentric cable supports secure installations in utility networks, service entrances, and underground feeds.

Understanding how these layers work together is key to selecting the correct cable and preventing system issues.

4. Concentric Cable Construction: Layer by Layer

Concentric cable construction is designed with multiple functional layers, each serving a specific role to ensure safety, conductivity, and durability.

From the central conductor to the outer jacket, every layer contributes to reliable electrical performance and system protection.

Central Conductor

The innermost part of a concentric cable is the central conductor, which is responsible for carrying the main electrical current. This conductor is usually made from either copper or aluminum.

Copper has higher electrical conductivity but is heavier and more expensive. Aluminum, while slightly less conductive, is lighter and more cost-effective.

The conductor may be solid or stranded. Stranded conductors are more flexible and are often used when the cable needs to bend during installation.

Insulation Layer

Surrounding the central conductor is an insulation layer that prevents electrical contact with the outer concentric wires. The most common insulation materials are cross-linked polyethylene (XLPE) and polyvinyl chloride (PVC).

XLPE has better thermal performance and can operate at higher temperatures, usually up to 90°C in continuous use. PVC is less expensive and suitable for applications where extreme heat is not a concern.

The insulation also resists moisture and chemicals, ensuring long-term operation in challenging environments.

Concentric Neutral or Ground Layer

After the insulation, a layer of conductors is helically wound around the core. These are typically bare or tinned copper wires, or aluminum wires, depending on the application.

This layer acts as the neutral return conductor in a power circuit or as a grounding shield. Its primary function is to carry fault current in the event of insulation failure and provide a continuous grounding path.

The size and number of wires depend on the cable’s ampacity and fault current rating. This layer also helps reduce electromagnetic interference by providing shielding.

Separator Tape (Optional)

Some concentric cables include a separator tape between the concentric wires and the outer jacket. This tape is usually made from polyester or Mylar and is added to simplify stripping and improve flexibility.

It is not always included but can be beneficial for specific installations where clean termination is required.

Outer Jacket

The final layer of the cable is the outer jacket, which protects the internal components from mechanical damage, environmental exposure, and chemical corrosion.

Materials like PVC, HDPE (High-Density Polyethylene), or LSZH (Low Smoke Zero Halogen) are used based on application needs. For direct burial cables, the jacket must be resistant to moisture, abrasion, and ultraviolet light.

The jacket also ensures compliance with safety regulations, especially for cables installed in public or high-risk areas.

5. Benefits of Concentric Cable Construction

The construction of concentric cable offers several practical advantages. First, the concentric arrangement provides a low-impedance path to ground, which enhances fault detection and improves protection device performance.

This makes the system safer and more responsive. Second, the mechanical balance of the cable allows it to be installed with ease, especially in tight bends or conduit runs.

The outer neutral wires also make the cable more robust under mechanical stress, including tension and compression. Another important benefit is electromagnetic shielding.

The concentric layer acts like a Faraday cage, minimizing electromagnetic interference with nearby communication cables or sensitive devices.

In metering and service entrance applications, the exposed neutral wires make tampering more difficult and allow for easy inspection.

Lastly, the cable’s design supports direct burial without the need for conduit, reducing installation time and cost.

These combined benefits make concentric cable a preferred choice for high-performance and low-maintenance electrical systems.

6. Applications in Detail

Concentric cables are used across various sectors due to their flexibility, strength, and electrical performance. In residential service drops, they provide reliable connection from transformers to homes.

The neutral wires offer consistent grounding and are visible for inspection. In commercial systems, they are often used for meter risers, especially where grounding requirements are strict.

Utility companies use them for underground feeder circuits because they can handle fault currents and environmental stress.

Concentric cables are also used in transformer secondary connections, where a strong neutral path is required to stabilize voltage.

In solar installations, they are used to connect inverters to panels or utility grids, especially in systems that require shielding from interference.

In industrial applications, concentric cables are chosen for control and grounding systems where EMI control is necessary.

Because of their shielding capabilities and durability, they are also found in street lighting, renewable energy systems, and rural electrification projects.

Their broad range of applications shows the versatility of this cable type.

7. Technical Standards and Compliance

To ensure safety and performance, concentric cables are manufactured according to several industry standards. In the United States, UL 854 covers service-entrance cable specifications, including insulation type, current rating, and environmental resistance.

The ICEA S-105-692 standard applies to aluminum concentric neutral cables, detailing mechanical and electrical performance requirements.

ASTM standards such as B800 and B801 define the materials and construction techniques for concentric lay conductors. These include guidelines for conductor stranding, wire gauge, and allowable tolerances.

IEEE 81 provides grounding requirements that relate to the design and usage of the concentric layer. In Canada, concentric cables must meet CSA C22.2 standards for armoured and non-armoured cables.

For installations involving fire safety, LSZH jackets may be required to comply with local building codes.

It’s also important to note that cables used in underground installations must meet standards for moisture resistance, impact resistance, and crush strength.

Always refer to manufacturer datasheets and local regulations to ensure full compliance with the intended application.

Conclusion

Concentric cable stands out as a dependable and efficient solution for modern electrical distribution systems.

Its structured design featuring a central conductor, insulating layer, concentric neutral or grounding wires, and a protective outer jacket ensures consistent electrical performance, strong mechanical integrity, and reliable fault handling.

Whether used in utility networks, residential service drops, or underground installations, this cable type delivers enhanced safety, stable grounding, and reduced electromagnetic interference.

By understanding its construction and function, professionals can make better installation choices, improve system reliability, and reduce maintenance risks.

Compliance with established industry standards like UL, ICEA, and IEEE further reinforces its suitability for critical applications.

In environments where cable failure is not an option, concentric cable offers a well-engineered and proven solution.

It’s not just about carrying current it’s about doing so with safety, efficiency, and long-term performance in mind. Selecting the right concentric cable starts with knowing how it works—and now you do.