Aerial power cables are a critical component of modern electrical distribution systems. Suspended high above the ground on poles or towers, these cables play a key role in delivering electricity across long distances especially in rural, semi-urban, and difficult-to-access areas.

Unlike underground systems, aerial cables are more exposed to environmental stress, mechanical wear, and safety hazards, making their quality and installation methods extremely important.

Failure to follow proper protocols can lead to frequent outages, electrical fires, and even serious injury.

Ensuring the performance and safety of aerial power lines isn’t about using the most expensive materials it’s about applying consistent, field-tested methods at every stage: from planning and cable selection to installation, inspection, and maintenance.

Industry standards, environmental conditions, and real-world challenges must all be considered to maintain reliability and reduce long-term costs.

In this guide, we will explain the practical methods and protocols used to ensure the quality and safety of Aerial Power Cables without relying on hype or jargon, just solid techniques that work.

Before any aerial cable is installed, it is essential to assess the environmental conditions of the project location. Environmental factors directly influence the type of materials, installation techniques, and maintenance requirements.

Key parameters to evaluate include wind pressure, temperature range, UV exposure, humidity, and the likelihood of snow, ice, or salt corrosion.

For example, in coastal areas, cables should be resistant to salt corrosion, while in high-altitude regions, insulation must withstand extreme cold.

Wind load and pole spacing must be calculated based on local wind speeds to prevent excessive cable sway or tension loss.

Understanding terrain conditions also helps in determining the most efficient pole placement and span length. Environmental data should be collected using reliable sources, such as local meteorological records or site surveys.

Ignoring these factors can lead to premature wear, increased sag, or even cable failure. A thorough environmental analysis sets the foundation for selecting appropriate materials and planning safe, reliable installations.

Selecting the correct type of aerial cable is critical for long-term performance and safety. The choice depends on voltage level, load demand, environmental exposure, and proximity to populated areas.

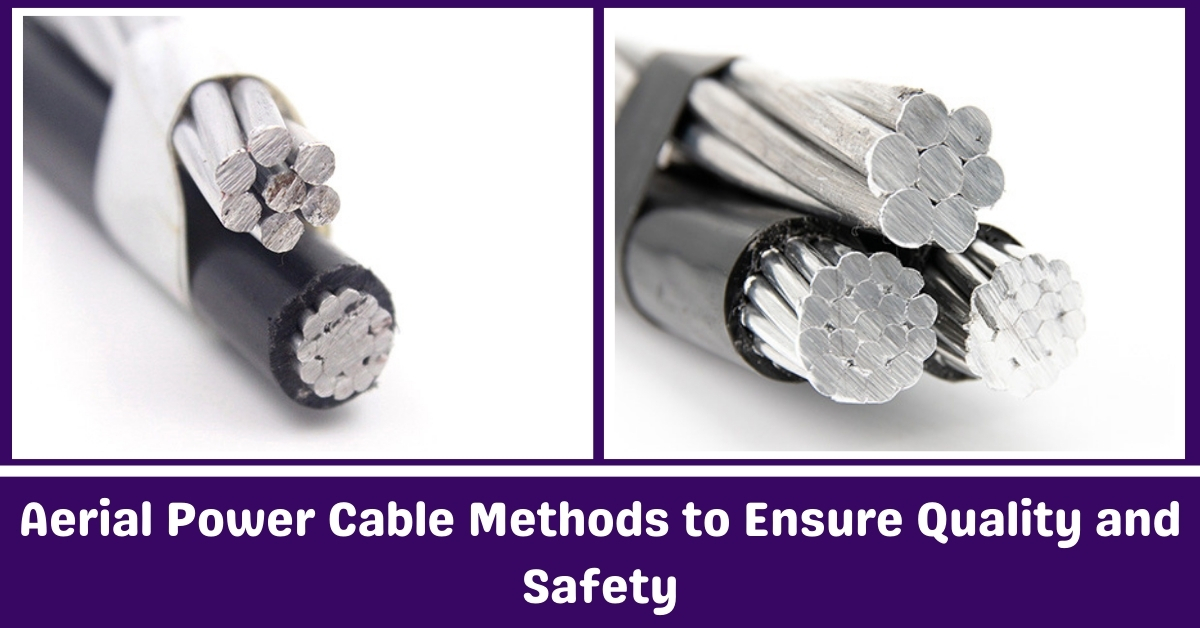

Common aerial power cable types include All-Dielectric Self-Supporting (ADSS), Aerial Bundled Cable (ABC), and various bare conductor types like ACSR, AAC, and AAAC.

ADSS cables are ideal for medium-voltage applications and areas prone to electromagnetic interference because they have no metallic parts. They are lightweight and self-supporting, simplifying installation.

ABC cables, on the other hand, are insulated and bundled together, making them suitable for low-voltage applications in residential or semi-urban areas where contact with trees or structures is a concern.

Bare conductors are widely used in high-voltage transmission due to their efficiency and low cost, but they require more space and safety clearances.

Each cable type has specific advantages, but matching the cable to its application and environment is key. Always refer to technical datasheets and comply with local regulations and standards to ensure safe and appropriate cable selection.

Proper installation is non-negotiable in aerial cable systems. All installation work must follow established engineering standards, including IEEE 524 for overhead line construction.

One of the most important aspects is proper tensioning. Over-tensioning can damage the cable or supporting structures, while under-tensioning can lead to sag, which poses safety and operational risks.

The correct tension should be calculated based on span length, aerial power cable weight, temperature, and wind load. Mechanical tensioners with calibrated indicators should be used to ensure accuracy.

Sag must also be precisely calculated using standard formulas or tension-sag charts provided by the cable manufacturer.

In general, the sag should allow for temperature expansion and contraction without compromising clearance or putting strain on connectors.

Minimum ground clearance must be maintained according to voltage level, typically ranging from 5.5 meters for low-voltage lines to 7.5 meters or more for high-voltage lines.

Always inspect poles, crossarms, insulators, and hardware before lifting cables. Every installation step should be documented and reviewed for compliance with engineering and safety standards.

Reliable joints and terminations are critical to prevent faults and maintain continuous electrical conductivity. Improper jointing is a leading cause of failures in aerial cable systems.

The first step is to use appropriate jointing kits—either heat shrink or cold shrink types—based on the cable type and environmental exposure. These kits ensure uniform insulation, mechanical protection, and environmental sealing.

All connections should be made using connectors that are compatible with the conductor material (eg, aluminum or copper) to avoid galvanic corrosion.

Crimping or compression tools should be calibrated, and connections should be made using the correct torque as specified by the manufacturer. Conductors must be properly cleaned and prepared before connection to avoid resistance buildup.

For terminations, especially on pole tops or transformer entries, mechanical strength and moisture resistance must be considered.

Sealing the ends using stress control tubing or sealant compounds prevents moisture ingress, which could degrade insulation over time.

Final joints and terminations should be visually inspected and tested before the system is energized.

Insulation testing ensures the cable’s integrity and suitability for operation. Before commissioning, every aerial cable must be tested for insulation resistance and dielectric strength.

The insulation resistance test is usually done using a megohmmeter (commonly 5kV rating) to ensure there are no insulation faults or moisture ingress.

Acceptable values depend on cable length and rating but should generally not fall below 1000 MΩ for every 1000 volts of operating voltage.

A HiPot test, or high potential test, subjects the aerial power cable to a voltage higher than its operating level to detect weaknesses that may not appear under normal conditions.

This test helps identify internal voids, insulation defects, or workmanship issues. All test results should be recorded and compared with manufacturer standards.

After physical stringing and jointing, repeat the insulation and continuity tests to confirm that no damage occurred during installation.

Ongoing insulation monitoring can also be used as part of predictive maintenance to catch issues early.

Security and wildlife protection are practical concerns for aerial installations. Theft of copper conductors and interference from birds, rodents, and reptiles can cause serious disruptions.

One effective theft deterrent is to use conductors with theft-resistant markings or non-copper materials like aluminum. Additionally, GPS-tracked cable tags and tamper-proof pole hardware can discourage unauthorized removal.

To guard against animals, install bird diverters or line markers to make the cables more visible. On poles, anti-climbing devices and animal guards can prevent rodents or snakes from reaching connection points.

In areas prone to bird nesting, deterrents like rotating mirrors or ultrasonic devices can also be helpful. Insulated cables like ABC are more resistant to wildlife-induced faults than bare conductors.

Regular inspection and installation of these guards reduce the chances of service interruptions, fire risks, and the need for reactive maintenance.

These measures are simple but effective and should be included in every aerial line design.

Aerial power cables require regular inspection to maintain long-term reliability and safety. Visual inspections should be scheduled at least every six months.

Inspections should check for signs of sagging, corrosion, broken strands, cracked insulators, and damage from vegetation or wildlife.

Any observed deviation from the original installation condition should be recorded and addressed.

Use of drones or telescopic equipment allows for safe and efficient inspection of high or hard-to-reach lines.

Additionally, infrared thermography can identify hotspots or overheating at connectors and joints, indicating possible resistance buildup or overload. Thermographic inspections should be performed annually.

Line tension and sag should be re-verified periodically, especially after major weather events or extreme temperature changes.

Insulator cleanliness is also critical dust, pollution, or salt deposits can cause tracking and flashover. Washing insulators with appropriate cleaning solutions or water jets helps maintain their effectiveness.

Preventive maintenance extends the life of aerial cables and reduces unplanned outages and emergency repairs, ultimately lowering operational costs.

Emergency preparedness ensures that damage to aerial power cables can be handled quickly and safely. Power lines are vulnerable to storms, vehicle impacts, fire, and falling trees.

Every utility or operator should have an emergency response plan that includes predefined protocols for different scenarios.

An emergency plan should include a spare parts inventory—cables, connectors, insulators, clamps, and other key components—so repairs can be done without delay.

Emergency response teams must be trained and available on short notice, with access to the necessary tools and protective equipment.

A communication plan should be established with local authorities, utility partners, and the public to handle outages or safety concerns.

Periodic drills should be conducted to test response times and the effectiveness of the procedures. Documentation of past incidents can help refine emergency protocols.

A well-organized emergency strategy ensures safety for personnel and the public while reducing downtime during unexpected events.

Accurate documentation and digital systems enhance the efficiency and reliability of aerial power systems. Every aspect of the cable system—from design and installation to inspections and maintenance should be logged and tracked.

Geographic Information Systems (GIS) can be used to map pole locations, span lengths, cable types, and joint positions.

Digital asset management systems can be linked to inspection schedules and test results, enabling automated reminders and historical trend analysis.

Integration with Supervisory Control and Data Acquisition (SCADA) systems allows real-time monitoring of current, voltage, temperature, and fault conditions across the aerial network.

This data supports predictive maintenance and helps in detecting issues before they become critical.

Modern sensors and Internet of Things (IoT) devices can also be installed to monitor conductor tension, sag, and vibration in real time.

Keeping detailed records not only simplifies compliance with regulatory audits but also improves operational decision-making and reduces human error.

Safe operation of aerial power systems depends on qualified personnel and strict adherence to safety protocols. Only trained and certified technicians should install, inspect, or maintain aerial cables.

Workers must be familiar with electrical safety standards, fall protection procedures, and the use of personal protective equipment (PPE).

All tools used should be tested for voltage rating and mechanical integrity. Safety guidelines must include safe distances from live conductors, minimum approach distances, and the use of insulated tools and platforms.

Work on energized lines should only be done using live-line maintenance techniques by trained professionals.

Regular safety training, including refresher courses every six months, ensures that field staff stay current with industry practices.

Safety audits should be conducted periodically to evaluate adherence and identify potential risks. A safety-first approach not only protects workers but also enhances the overall reliability and reputation of the power distribution system.

Ensuring the quality and safety of aerial power cables is not a single-step task it is a continuous process involving careful planning, proper execution, and ongoing maintenance.

Each phase, from understanding the environment to choosing the right aerial power cable , following strict installation procedures, testing insulation, and applying anti-theft or animal protection measures, plays a crucial role in long-term system reliability.

Consistent inspection routines and emergency preparedness help detect issues early and respond effectively to unplanned events, while accurate documentation and digital monitoring tools support smarter, data-driven maintenance decisions.

Equally important is the emphasis on worker training and strict adherence to safety protocols, which protect both personnel and infrastructure.

When each of these elements is implemented correctly and consistently, the result is a more dependable, cost-effective aerial power system.

This practical, step-by-step approach helps prevent system failures, reduce downtime, and ensure the safe delivery of electricity in various environments and applications.

In short, quality and safety in aerial cabling don’t happen by chance they’re the result of detailed planning, skilled execution, and disciplined follow-through.